close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-08-08 Origin: Site

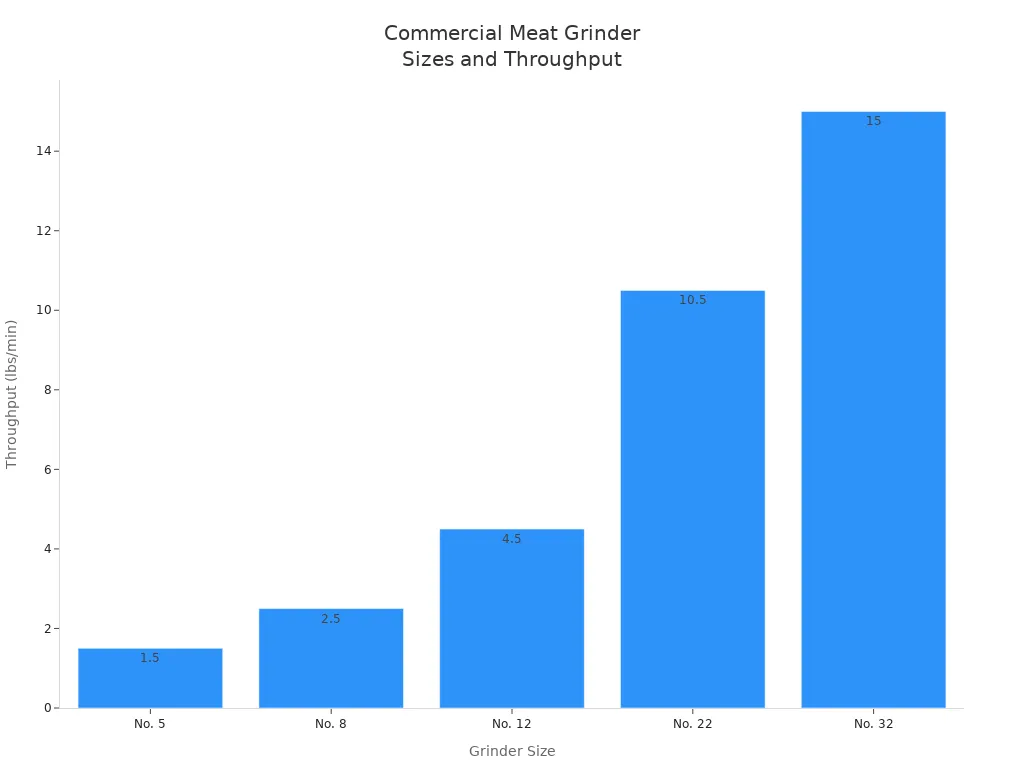

You face many choices when you select commercial meat grinders for your business. You see different types like countertop, floor, and bench models, each offering unique pros and cons. Sizes matter just as much. For example, a #8 meat grinder fits small kitchens, while a #32 works best in processing facilities. Plate sizes, from 1/8 inch to 3/4 inch, change the grind texture. You need to think about safety, too, since high-powered machines require safe operation. Horus, a China factory and wholesaler, offers custom options to fit your needs. Take a look at the chart below to compare throughput by grinder size:

Grinder Size | Plate Diameter | Approx. Throughput (lbs/min) | Typical Use |

|---|---|---|---|

No. 5 | ~2 1/8" | 1–2 | Light-duty or home use |

No. 8 | ~2 1/2" | 2–3 | Small kitchens, ghost kitchens |

No. 12 | ~2 3/4" | 4–5 | Mid-sized restaurants |

No. 22 | ~3 1/4" | 9–12 | High-volume kitchens, butcher shops |

No. 32 | ~3 7/8" | 15+ | Butcher shops, processing facilities |

You get better results and improved safety when you match the right meat grinder to your company’s needs.

Pick the right meat grinder size for your business. This helps you work faster and stay safe.

Manual grinders are good for small jobs and are simple to use. Electric grinders can grind a lot of meat very fast.

Plate size changes how the meat looks. Small holes make the meat fine. Big holes make the meat chunky.

Find grinders with strong motors and stainless steel parts. Safety features help the grinder last longer and keep you safe.

Clean your grinder every time you use it. Keep the plates sharp to keep the meat good and stop machine problems.

When you pick a meat grinder, you see two main types. These are manual and electric. Each type works best for different jobs. Some are good for restaurants or food factories. The best one for you depends on your kitchen size. It also depends on how much meat you grind and how much time you have.

A manual meat grinder works with a hand crank. You turn the handle to grind meat. You can control how fast or slow you go. This type is simple and easy to move. It is also easy to clean. You do not need power, so you can use it anywhere. Many small kitchens or food carts in China and other places use manual grinders. They are quiet and do not cost much. They are good for small amounts of meat or if you want to do it by hand.

Tip: Manual grinders work best if you do not grind meat often or need a backup.

Advantages of manual meat grinders:

They cost less and last a long time.

They have fewer parts, so they break less.

They are easy to fix and keep clean.

They are quiet when you use them.

Disadvantages:

They make your arms tired if you grind a lot.

They are slower than electric grinders.

You need a counter edge to attach them.

It is hard to keep the grind size the same.

Manual grinders are good if you only grind a little meat. They are also good if you need to move them. Busy kitchens do not use them much. They take more work and time.

An electric meat grinder uses a motor to grind meat fast. You do not need to use your hands much. It gives steady power and can grind a lot at once. Many electric grinders come from China and have special features. You see electric grinders in restaurants and butcher shops.

Key features of electric meat grinders:

Strong motors (1 HP or more) for tough meat.

Stainless steel parts for strength and easy cleaning.

Many tools for making sausage or shredding.

Safety switches and parts that stop it from breaking.

Benefits:

Saves you time and hard work.

Makes the meat grind the same every time.

Can grind a lot of meat at once.

Lets you make more kinds of food.

Electric grinders help your kitchen work faster and keep food good. You can buy lots of meat and mix your own blends.

Category Type | Description |

|---|---|

Electric Meat Grinders | Go from small countertop types to big floor models for lots of meat. |

Manual Meat Grinders | Smaller, cheaper types for less meat or home use. |

Electric grinders cost more and need power to run. They are heavy and may need two people to move. Cleaning takes longer because there are more parts. But you get more speed and can do more things with them.

When you choose a meat grinder, you see different sizes. These sizes matter because they affect how much meat you can process and how fast you can work. The most common meat grinder hub sizes are #8, #12, #22, #32, and #42. Each size fits a different business need. You can find these sizes in many China factory and manufacturer catalogs, including custom and OEM options for sale.

Grinder Size | Hub Diameter | Plate Size | Typical Grind Texture | Motor Power (Range) | Weight (Range) | Dimensions (L x W x H) |

|---|---|---|---|---|---|---|

#8 | ~2.5" | 1/8"–3/16" | Fine | 0.5–0.75 HP | 15–25 lbs | 14" x 7" x 14" |

#12 | ~2.75" | 3/16" | Medium | 0.75–1 HP | 20–35 lbs | 16" x 9" x 17" |

#22 | ~3.25" | 1/4" | Coarse | 1–1.5 HP | 37–52 lbs | 19" x 24" x 12" |

#32 | ~3.88" | 3/8" | Chili/Coarse | 1.5–2 HP | 60–80 lbs | 20" x 28" x 16" |

#42 | ~5" | 1/2" | Stew/Very Coarse | 2–5 HP | 100+ lbs | 24" x 36" x 20" |

Tip: The hub size tells you which attachments fit your machine. Plate size controls the texture of your grind. Smaller holes give you a finer grind, while larger holes make it coarser and faster.

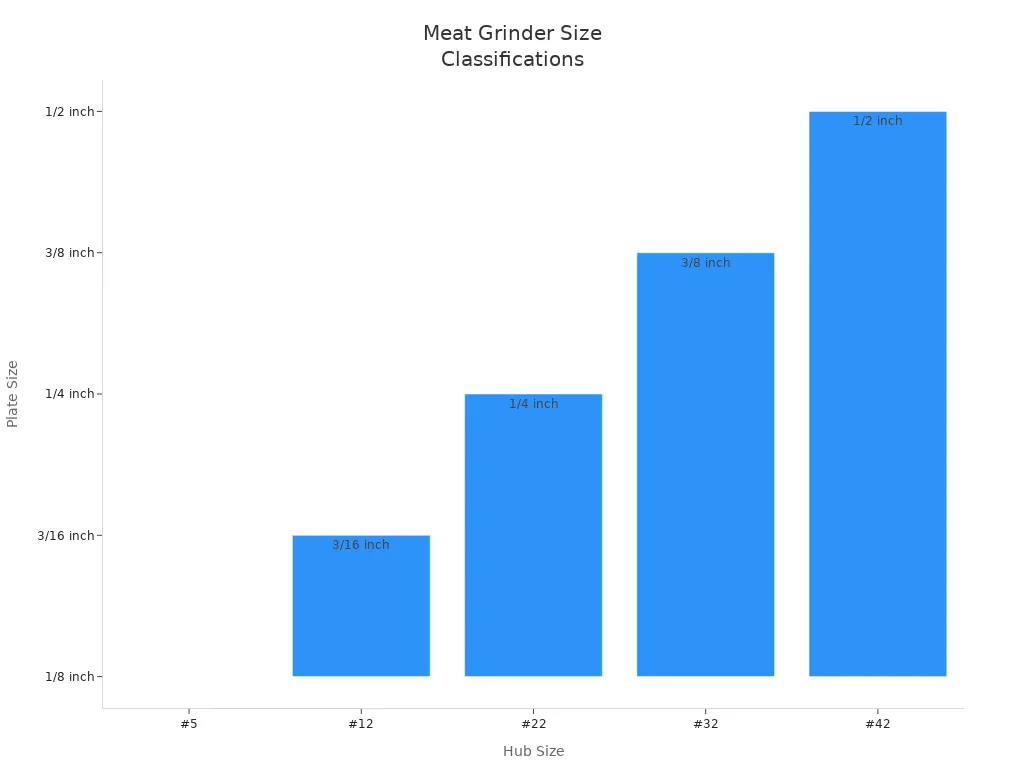

You can see how plate size and hub size work together in this chart:

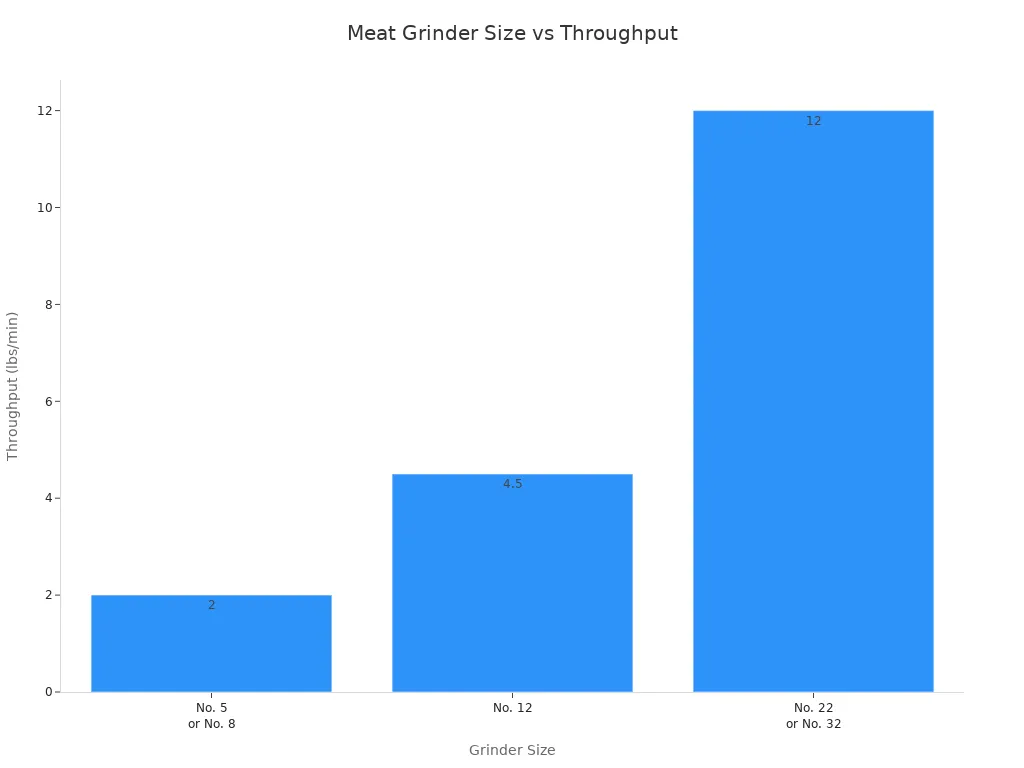

You need to match the right meat grinder hub sizes to your business. Each size works best for a certain volume and type of operation. If you run a small restaurant or ghost kitchen, you may only need a #8 or #12. Larger butcher shops or processing plants often use #22, #32, or even #42 for bulk production.

Grinder Size | Typical Use Case | Output Capacity (lbs/hr) | Business Examples |

|---|---|---|---|

#8 | Light-duty, test kitchens, small restaurants | 60–120 | Small cafes, food trucks |

#12 | Light-duty, small delis, daily restaurant use | 460–540 | Mid-sized restaurants, catering |

#22 | Medium-duty, butcher shops, grocery stores | 528 | Butcher shops, grocery stores |

#32 | Heavy-duty, large butcher shops, commissary kitchens | 800+ | Meat processing facilities, wholesalers |

#42 | Industrial, continuous high-volume production | 1500+ | Large factories, custom meat exporters |

You can see how throughput increases as you move up in size:

Small Businesses:

If you own a small deli or café, a #8 or #12 meat grinder gives you enough power for daily needs. These sizes are compact and easy to clean. You save space and money.

Medium Businesses:

For a busy restaurant or butcher shop, a #22 meat grinder offers more power and higher output. You can grind meat faster and keep up with customer orders.

Heavy-Duty Operations:

If you run a large processing facility or need to grind meat in bulk, choose a #32 or #42. These sizes handle continuous use and large batches. They have strong motors and durable parts.

Note: Always match your meat grinder hub sizes to your production volume. Using a grinder that is too small can slow your work and wear out the machine. A grinder that is too large may waste energy and space.

You see that each meat grinder size comes with different motor power and weight. For example, a #22 grinder often has a 1 HP motor and weighs about 50 lbs. A #32 grinder can have a 2 HP motor and weigh over 70 lbs. The largest #42 models may use up to 5 HP and weigh more than 100 lbs. These details help you plan your kitchen layout and power needs.

You control the grind texture by changing the plate size. Fine plates (1/8 inch) make smooth sausage. Medium plates (3/16 inch) work well for hamburger. Coarse plates (1/4 inch or larger) are best for chili or stew. You can switch plates on most commercial meat grinders to get the texture you want.

Hub Size | Plate Size | Typical Ground Meat Type |

|---|---|---|

#5 | 1/8 inch | Fine sausage |

#12 | 3/16 inch | Medium hamburger |

#22 | 1/4 inch | Coarse sausage |

#32 | 3/8 inch | Chili |

#42 | 1/2 inch | Stew |

You must always use safe practices when you operate any size meat grinder. Never reach into the feed tube. Always use the food pusher. Wear gloves and keep the area clean. Do not overload the machine. Clean and dry all parts after use. These steps keep your operation safe and improve efficiency.

Safety Reminder: Choose the right size for your needs. This helps you avoid overworking the machine and keeps your staff safe.

If you need help picking the right meat grinder, Horus, a meat processing machinery provider in China, offers expert advice. You can ask for custom solutions or bulk orders to fit your business.

You need to choose the right plates for your meat grinder to get the best results. Each plate type gives you a different grind and texture. The most common grinding plates include standard hub plates, reversible hub plates, kidney plates, and fine grinder plates. These plates come in many meat grinder plate sizes, so you can match them to your needs.

Hub Size | Plate Hole Size | Typical Ground Meat Type |

|---|---|---|

#5 | 1/8 inch | Fine sausage |

#12 | 3/16 inch | Medium hamburger |

#22 | 1/4 inch | Coarse sausage |

#32 | 3/8 inch | Chili |

#42 | 1/2 inch | Stew |

You can see how meat grinder plate sizes affect the texture. Smaller holes make fine, smooth meat for sausages. Larger holes create a chunky grind for chili or stew.

Standard hub plates work for most grinding jobs. You can use them for burgers, pork, or sausage.

Reversible hub plates last longer. You flip them to use both sides, which helps in high-volume kitchens.

Kidney plates have slots for draining liquid. They help when you want less moisture in your patties or sausages.

Fine grinder plates give you a smooth, even grind. These plates work best for pates or emulsified sausages.

Tip: Always keep your grinding plates and knives paired and sharp. Good sharpness means cleaner cuts, better texture, and less chance of jams.

The right plate and sharpness help you control the quality of your ground meat. You should keep your plates sharp and clean. Dull plates can make meat mushy and slow down your work.

The Unger system gives you more control over your grind. You find this system in large commercial meat grinders, often from China factory or OEM suppliers. The Unger system uses several plates and double-edged knives. It often starts with a kidney plate, then a knife, and then more grinding plates. This setup lets you get a finer and more even grind, even for big batches.

Unlike the simpler Enterprise system, the Unger system works best for high-capacity jobs. You see it in large processing plants or when you need to grind meat below 8mm. The Unger system can handle tough jobs, including frozen meat, and keeps the sharpness of the plates longer.

Note: The Unger system helps you get the exact texture you want. It also protects your grinder parts and keeps your operation running smoothly.

You should choose the right grinding plates and system for your business. The right choice means better texture, higher output, and less downtime. Always check the sharpness of your plates and replace them when needed.

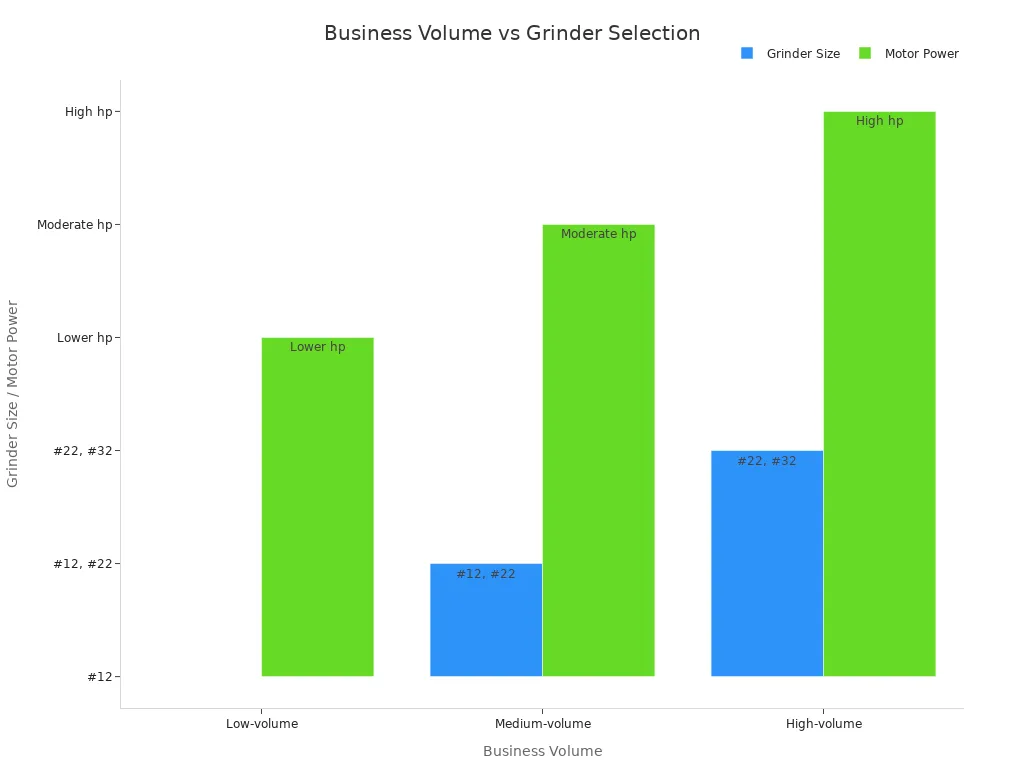

Picking the right commercial meat grinder is important for your business. It affects how you work, the quality of your food, and how much you spend over time. You need to choose a grinder that matches how much meat you process each day. Think about the texture you want and the features that keep your kitchen safe and running well. Horus, a China factory and manufacturer, can make custom grinders for any need. Use this guide to help you decide.

How much meat you grind each day helps you pick the right grinder. If you own a small deli or café, you need a light-duty machine. Big butcher shops or meat plants need heavy-duty grinders. The right size and motor power help you keep up with orders and protect your machine.

Business Volume | Grinder Type | Characteristics | Suitable For | Grinder Size Examples | Motor Power Impact |

|---|---|---|---|---|---|

Low-volume | Light-duty | Compact, affordable, suitable for occasional use, not for continuous heavy grinding | Small delis, catering businesses | #12 grinders | Lower horsepower, less capacity |

Medium-volume | Medium-duty | More powerful and durable, faster processing rates, balance between performance and cost | Butcher shops, restaurants with moderate needs | #12, #22 grinders | Moderate horsepower, handles frequent use |

High-volume | Heavy-duty | Powerful motors, robust construction, designed for continuous, large-scale grinding | Large butcher shops, meat processing plants | #22, #32 grinders | High horsepower, processes large quantities efficiently |

A 1.5 HP electric meat grinder can grind over 1,000 pounds of meat in one hour. This is good for big butcher shops, busy restaurants, and meat plants. Smaller electric or manual grinders, like #8 or #12, are best for small kitchens or ghost kitchens. Always pick a grinder that matches how much meat you need to grind.

Tip: If you guess too low, your grinder will wear out fast. If you guess too high, you waste space and power.

The way your ground meat feels depends on the plates you use and how many times you grind it. You can change the grind by picking different plate hole sizes. Small holes make fine, smooth meat. Big holes give you chunky, coarse meat. Use fine plates for hot dogs. Use coarse plates for sausages or chili.

Hub Size | Plate Hole Size | Typical Ground Meat Texture/Type |

|---|---|---|

#5 | 1/8 inch | Fine grind, suitable for fine sausages |

#12 | 3/16 inch | Medium grind, good for hamburgers |

#22 | 1/4 inch | Coarse grind, ideal for coarse sausages |

#32 | 3/8 inch | Coarser grind, used for chili |

#42 | 1/2 inch | Very coarse grind, suitable for stew |

If you want coarse meat, grind once with a large plate. For finer meat, grind twice—first with a coarse plate, then with a fine one. Electric grinders make this quick and even. Manual grinders give you more control but take more work. Always use the right plate for the texture you want.

Note: The right plate and number of grinds help you get the best meat for your menu.

When you pick a commercial meat grinder, look for features that make it safe, strong, and easy to use. Stainless steel is best because it does not rust and is easy to clean. Strong motors (1 HP or more) can handle tough jobs and lots of use. Plates and attachments you can swap out let you make different foods.

Feature | Importance for Long-Term Reliability |

|---|---|

Motor Strength | Preferably 1HP or more for efficient, fast grinding and durability. Stronger motors handle higher workloads better. |

Grinding Plates | Interchangeable blades with various sizes (coarse, medium, fine) provide versatility and allow customization of texture. |

Construction Materials | Stainless steel is ideal for durability, rust resistance, and ease of cleaning. |

Safety Features | Emergency stop, interlocks, overload protection, reverse function, and non-slip feet reduce injury risk and protect the machine. |

Build Quality | All-stainless steel construction and metal gear-driven components enhance durability and longevity. |

Maintenance Practices | Regular cleaning, blade sharpening, and avoiding overloading are critical to prolonging the grinder's lifespan. |

Matching Motor to Needs | Choosing motor power and grinding capacity appropriate to business volume ensures reliable performance over time. |

Electric grinders often have safety features like overload protection, emergency stops, and non-slip feet. Manual grinders have fewer parts, so they are easier to clean and fix. Always check if the plates and parts are easy to remove. This makes cleaning faster and helps stop germs from spreading.

Safety Alert: Always check for safety. Use the food pusher, keep your hands away from moving parts, and clean all plates and blades after every use.

Use this checklist to help you compare commercial meat grinders:

Does the grinder match how much meat you grind each day?

Is the motor strong enough (1 HP or more for most businesses)?

Are the plates and blades easy to change and clean?

Can you get the grind texture you need (fine, medium, coarse)?

Is it made of stainless steel for strength and easy cleaning?

Does it have safety features (emergency stop, overload protection, non-slip feet)?

Can you get replacement parts and help from the maker or seller?

Does the grinder fit in your kitchen?

Is it easy and quick to clean and take care of?

Picking the right commercial meat grinder means thinking about how much meat you grind, the texture you want, and the features you need. You get better results, save time, and keep your kitchen safe when you choose the right machine.

You choose better when you pick the right meat grinder for your business. The right grinder means less waiting and safer work. Cleaning and taking care of your grinder makes it last longer. Look at the checklist and tables to help you decide. Picking well helps you make more money and get better meat.

Tip: Horus, a China factory and wholesaler, can make custom and OEM commercial meat grinders for sale. You can order in bulk, ask for special attachments, or get unique sizes for your business.

You should pick a #8 or #12 grinder. These sizes fit small kitchens and daily needs. They save space and cost less.

You need to clean your grinder after every use. This keeps meat safe and the machine working well. Always follow the cleaning steps from your factory or manufacturer.

Yes, you can. You should clean the grinder between uses. This stops flavors from mixing.

Look for emergency stops, overload protection, and non-slip feet. These features keep you and your staff safe.

Yes, you do. Fine plates work best for sausage. Medium plates make good hamburger.