close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-08-12 Origin: Site

You will spot the main difference between a #8 and #12 meat grinder in size and power. A #12 model handles more meat, grinds faster, and suits bulk processing. You might choose #8 for home use. Many manufacturers, including Horus in China, supply both types for custom needs.

Choose a #8 meat grinder for home use or small batches; it is compact, lighter, and fits well in small kitchens.

Pick a #12 meat grinder for commercial or bulk processing; it has a larger plate, stronger motor, and grinds meat faster.

Always match grinder plates and blades to your model and keep parts sharp and clean for the best grinding results.

When you look at a meat grinder, you may wonder what the numbers mean. The #8 and #12 labels show the size of the grinder plate. This plate has holes that control how fine or coarse your ground meat will be. The number refers to the plate's diameter, usually measured in millimeters.

Here is a quick comparison:

Grinder Size | Plate Diameter (inches) | Plate Diameter (mm) | Notes |

|---|---|---|---|

#8 | ~2.375 | ~60 | Standard diameter, widely used |

#12 | Larger than #8 | Larger than 60 | Uses #12 plates, fits bigger batches |

A #8 plate measures about 60 mm across. A #12 plate is even larger, which means it can handle more meat at once. You will find that the plate size affects the texture of your ground meat. Smaller holes make a finer grind, perfect for smooth sausages or hamburger patties. Larger holes give you a chunkier texture, great for chili or rustic sausages. If you want to experiment, try different plate sizes to see how they change the meat's texture. Many manufacturers, including those in China, offer custom plate sizes to fit your needs.

Tip: For the best results, keep your grinder knives sharp and match them to the plate. This helps you avoid mushy meat and keeps the texture just right.

The physical size of a meat grinder matters, especially if you have limited space or need to process large amounts of meat. The #12 model is bigger and heavier than the #8. It also has a wider throat opening, so you can feed in larger chunks of meat without cutting them down as much.

Here is a table comparing typical models:

Grinder Model | Dimensions (L x W x H) | Weight | Throat Opening |

|---|---|---|---|

#12 Meat Grinder (Omcan) | 16" x 13" x 11" | 14 lbs | Approximately 2" |

#8 Meat Grinder PRO (Sausagemaker) | 19" x 19" x 19" | 42-44 lbs | Not specified |

You can see that the #12 grinder is often more compact but has a larger throat. The #8 model can be heavier, depending on the brand and build. Companies like Horus in China supply both sizes for sale, and you can find custom made options to fit your kitchen or factory needs. If you plan to grind meat in bulk, a larger throat and plate will save you time and effort.

Note: Always check the dimensions before you buy. Make sure the grinder fits your workspace and matches your processing needs.

The size of your grinder affects not just how much meat you can process, but also the quality of the grind. A larger plate and throat mean faster grinding and less prep work. If you run a restaurant, test kitchen, or need a reliable provider for wholesale supply, a #12 model may suit you better. For home cooks, a #8 meat grinder often works well and takes up less space.

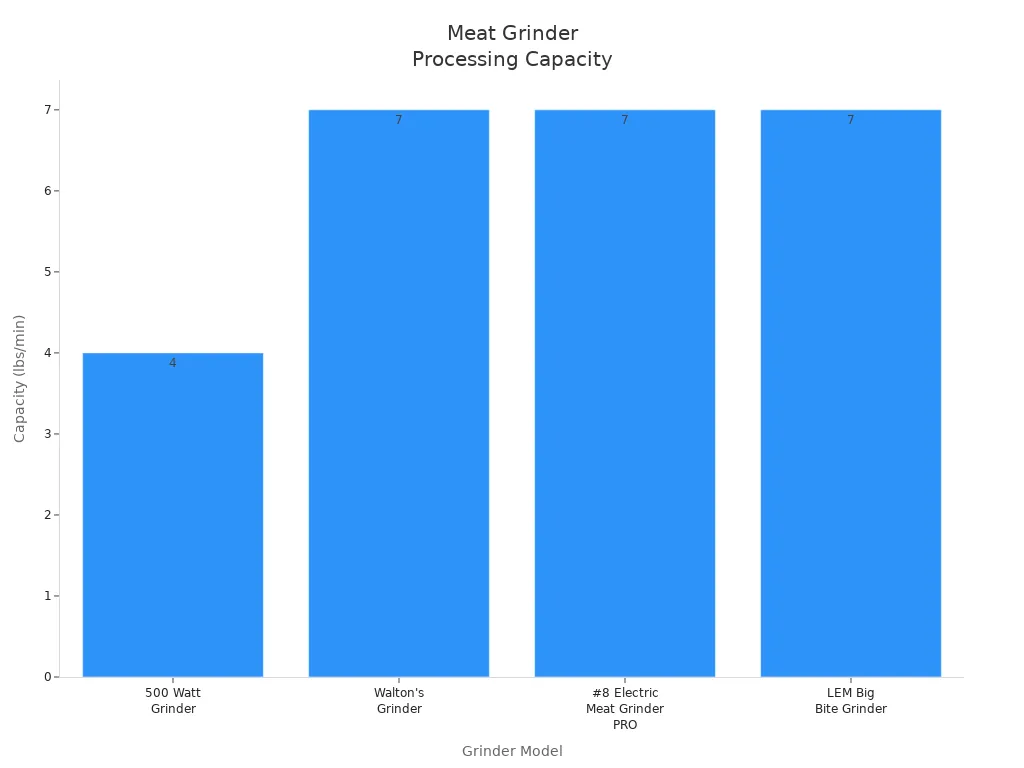

When you choose a meat grinder, you want to know how much meat it can handle. Throughput means the amount of meat you can process in a set time. You see big differences between #8 and #12 models. Companies in China, like Horus, supply both types for sale, so you can pick the right one for your kitchen, factory, or restaurant.

Here is a table showing how much meat each grinder can process:

Grinder Model | Grinder Size | Processing Capacity (lbs/min) | Processing Capacity (lbs/hour) |

|---|---|---|---|

500 Watt Grinder | #12 | 4 | 240 |

Walton's Grinder | #12 | 7 | 420 |

#8 Electric Meat Grinder PRO | #8 | 5.5 - 10 | 330 - 600 |

LEM Big Bite Grinder | #8 | ~7 | 420 |

You see that #8 grinders can process between 5.5 and 10 pounds per minute. Some models reach up to 7 pounds per minute. #12 grinders usually handle 4 to 7 pounds per minute. If you need to process meat in bulk, a #12 grinder from a manufacturer or factory in China can help you save time. Many companies offer custom made grinders for wholesale and export.

Tip: If you run a ghost kitchen or a mid-sized restaurant, you may want a grinder with higher throughput. It helps you keep up with demand and reduces waiting time.

Speed matters when you grind meat for large batches. You want a grinder that works fast and does not slow you down. #12 grinders work faster than #8 models, especially when you need to process meat for sale or supply. You can see the difference in grinding speed in the table below:

Grinder Model | Motor Power | Grinding Speed (lbs/min) | Notes |

|---|---|---|---|

Weston Pro Series #8 | 0.75 HP | 4-6 | Suitable for household use, lower power |

Walton's #12 | 0.75 HP | 7 | Medium-sized batches, faster grinding |

A #12 grinder can process up to 7 pounds per minute. It works well for bulk orders and commercial kitchens. You get faster results and less downtime. #8 grinders handle 4 to 6 pounds per minute. They suit home cooks and small restaurants.

You see from the chart that #12 grinders offer higher speed for larger batches. If you need a grinder for wholesale or factory use, you may want to choose a #12 model from a trusted provider or distributor in China. Many vendors offer custom options for export and supply.

Note: Always check the specifications before you buy. You want a grinder that matches your speed and throughput needs. If you process meat for bulk orders, a #12 grinder gives you the best value.

When you look at a meat grinder, you notice the motor strength first. The horsepower (HP) tells you how powerful it is. Most #8 grinders use a 0.5 HP motor. Many #12 grinders use a 0.75 HP motor, but some models go up to 1 HP. You can see the difference in the table below:

Grinder Model | Head Size | Motor Horsepower (HP) |

|---|---|---|

LEM Big Bite 17791 | #8 | 0.5 |

LEM Big Bite 1780 | #12 | 0.75 |

Thunderbird 300E | #12 | 1 |

Walton's #12 Meat Grinder comes equipped with a 0.75 HP motor. This rating is common for #12 grinders. You get more power for bulk grinding and tougher jobs. Many factories and manufacturers in China offer custom made grinders for sale, so you can choose the motor strength that fits your needs.

Tip: A stronger motor helps you grind meat faster and with less effort. It also protects the grinder from overheating during long sessions.

You want your grinder to handle tough meat. A #12 model with a 0.75 HP or higher motor can grind partially frozen meat and sinew with ease. You do not need to worry about jams or slowdowns. A #8 grinder works well for softer cuts and smaller batches. If you run a restaurant, ghost kitchen, or need a reliable supply for wholesale, a #12 grinder from a trusted provider in China gives you better performance.

You should always clean all parts after each use. Use warm, soapy water and dry everything well. Sharpen blades often to keep grinding smooth and protect the motor. Lubricate moving parts and inspect for wear. These steps help your grinder last longer and work better.

Note: Avoid grinding bones unless your grinder is designed for it. This keeps the motor safe and prevents damage.

A #8 meat grinder works well in most kitchens. It fits in small places and handles enough meat for families. Many people use this size to make burgers, sausages, or food for pets. You can buy these grinders from companies in China, and some offer custom made choices. Some people have problems with smaller grinders:

Motors can break if you grind too much meat.

The back part gets hot during long use.

Aluminum parts can react to heat and cleaning products, so cleaning is harder.

Grinding can be slow, especially with attachments.

Sometimes the grinder gets stuck, but a reverse button can help.

Using a foot pedal makes grinding easier and keeps it cooler.

If you grind meat a lot or want to do big batches, you might want a grinder with a bigger neck and stronger motor. Buying a better or commercial grinder saves time and avoids problems.

If you work in a restaurant or test kitchen, you need a strong grinder. The #12 model is good for this job. It has a tough motor and is made of stainless steel. You can grind up to 250 pounds of meat every hour. This fast speed helps you fill orders and do less work by hand. Many factories in China sell #12 grinders for wholesale or export. These grinders have gear-driven parts and helpful extras. They last longer and work faster. The #12 size gives you power but does not take up too much space, so it is great for busy kitchens and mid-sized restaurants.

You want your grinder to work well each time you use it. The plates and blades are very important for how your machine works. You must use the right plate and blade size for your grinder. #8 and #12 grinders need different parts, so you cannot use the same ones. Companies in China, like Horus, make custom stainless steel plates and knives for sale. These parts come in different thicknesses, like 1/4", 3/8", and 1/2". You can choose the size that fits your needs.

Here is a table that shows which parts fit each grinder:

Grinder Size | Compatible Plates and Blades | Plate Thickness Options | Interchangeability Notes |

|---|---|---|---|

#8 | Stainless steel plates and knives | 1/4", 3/8", 1/2" | Only fits #8 grinders |

#10/#12 | Stainless steel plates and knives | 1/4", 3/8", 1/2", 3/4" | #10 and #12 parts often interchangeable |

You can see that #10 and #12 parts can be used together, but #8 parts only fit #8 grinders.

Tip: Always check your grinder size before buying new plates or blades. This helps you avoid mistakes and keeps your machine working well.

Accessory choices let you do more in your kitchen or factory. You can use stuffing tubes to make sausage, meat stompers to feed meat safely, and different plates for different textures. Stainless steel knives and feeder pans make cleaning easier and help you cut better.

You want your grinder to last for many years. Replacement parts help you fix problems and keep your machine working. #12 grinders from big companies have many parts you can buy for supply and export. You can get sausage stuffer flanges, tubes, retaining rings, oil seal plugs, nylon washers, locking thumbscrews, augers, grinding chamber heads, rubber feet, worm wheel gears, and worm shaft assemblies.

Here is a table that shows what parts you can get:

Grinder Model | Replacement Parts Available | Examples of Parts |

|---|---|---|

#12 | Many options | Sausage stuffer flanges, tubes, retaining rings, oil seal plugs, nylon washers, locking thumbscrews, augers, grinding chamber heads, rubber feet, worm wheel gears, worm shaft assemblies |

#8 | Few options | Not listed |

You can see that #12 grinders have more replacement parts for sale. Factories and providers in China offer these parts for wholesale and custom orders. #8 grinders have fewer choices, so you may need to ask your vendor or distributor.

If you want your grinder to work well for a long time, keep extra parts ready. This makes fixing problems easy and helps you avoid waiting for repairs.

When you pick a #8 or #12 meat grinder, think about your kitchen size. You also need to know how much meat you want to grind. Think about how often you will use the grinder. Each model is good for different jobs. Look at the table below to see the main differences:

Factor | #8 Meat Grinder | #12 Meat Grinder |

|---|---|---|

Size | Compact, fits home kitchens | Larger, heavy-duty, still fits on countertops |

Intended Use | Small batches, pet food, burgers | Higher volume, commercial or small business use |

Motor Power | Less powerful | More powerful motor (often 1HP) |

Production Capacity | Good for low volume | Can process 250 lbs/hour or more |

Grind Texture | Finer grind | Coarser grind |

Durability | For lighter use | Heavy-duty, stainless steel, gear-driven |

Ease of Use | Simple, light, easy to move | Needs more space, easy to clean and maintain |

Versatility | Great for home and small tasks | Handles many meats, fruits, and vegetables |

Price Range | Lower | Higher, but more power and capacity |

You should also remember these things:

Stainless steel and aluminum parts last longer and are easier to clean.

#8 grinders fit in small kitchens. #12 grinders need more room but work faster.

#8 models are lighter and easy to use. #12 models often have electric buttons like forward and reverse.

Both types should come apart for cleaning. Stainless steel needs care to keep it shiny.

#12 grinders cost more, but they give you more power and speed.

Home cooks or small shops usually pick #8. Restaurants or busy kitchens pick #12 for grinding lots of meat.

You see big differences between #8 and #12 meat grinder models. The table below shows key features:

Feature | #8 Meat Grinder | #12 Meat Grinder |

|---|---|---|

Motor Power | 3/4 HP | 1 HP |

Grinding Capacity | 2-3 lbs/min | 12-14 lbs/min |

If you cook at home, pick #8 for small batches. For busy kitchens or bulk supply, choose #12 from a China factory or manufacturer. Think about your needs before you buy. You get better results when you match your meat grinder to your usage.

You make the best choice when you know your kitchen and your goals.

You see a bigger plate and stronger motor in #12. It grinds more meat faster.

No, you cannot. Each grinder needs its own plate size.

You get better results with a #12 grinder. It handles large batches quickly.